With the ACP sag correction system SCS can remove sags or low spots in PVC sewer lines from inside the pipe.

How it Works

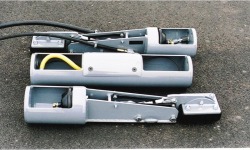

The three sections of the sag remover are assembled inside a manhole. Two air hoses are connected. One to supply a pneumatic powered vibrator and one to power the lift mechanism.

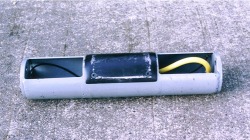

After the machine is positioned in the sag, lift pressure is applied. This forces the center section, which contains the vibrator, against the top of the pipe. The combination of lift pressure and vibration will raise the pipe.

Most of the lifting power comes from the centrifugal force of the vibrator. The rubber isolater pads at the ends of the machine and the air suspension of the lift mechanism prevents this vibration energy from transfering downward.

Intense high frequency vibration allows the surrounding granular bedding material to flow from above the pipe to underneath, as the pipe is lifted.

Sags of any length can be removed by moving the machine in increments and lifting along the length of the sag. Deeper sags will require multiple passes.

The 8 inch pipe adapter bolts to the center section of the sag machine. It allows the machine to lift above parallel when removing sags longer than the span of the machine.

It is replaced with other pipe adapters for larger diameter pipes.

It is replaced with other pipe adapters for larger diameter pipes.