SCS offers another innovative trenchless method offered for rehabilitation of existing sewers is the installation of cured-in-place pipe liners. This method restores the structural integrity of the pipe, eliminates infiltration and in many cases, can increase the hydraulic capacity of the original pipe. This technology can be used for complete manhole-to-manhole-repairs or for point repairs.

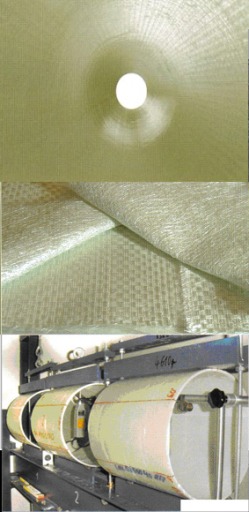

Relining is normally associated with reduced flow capacity and insufficient conformity to the old pipe. The unique material construction of the seamless MultiLiner® eliminates such problems.

In addition, the smooth inner surface produced using MultiLiner® actually increases the flow within the lined pipe, especially as compared to the old host pipe.

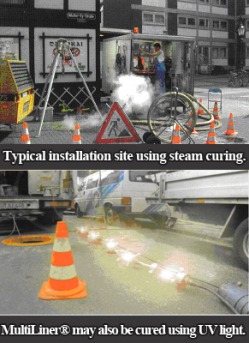

MultiLiner® is typically cured by stream. Using a small steam generator or boiler unit facilitates relining in industrial environments, confined, places, underground and even on board ships.

Air inflates the liner tightly against the inside of the pipeline and the steam is gradually added until the activation temperature is reached. After the chemical reaction has hardened the resin, postcuring begins with pure steam at 230 F/110 C. The postcuring develops full resin strength and chemical resistance. The total installation time is normally 5 to 6 hours.

With a flexural modulus in excess of 1,200,000 psi the patented MultiLiner® is the strongest CIPP liner on the market today. With such strength performance customers can expect to install liners with a much thinner wall thickness thus providing their customers with a higher flow capacity for a competitive price.

The patented MultiLiner® exceeds all the requirements for ASTM F2019. In addition MultiLiner® can also be expected to far exceed the requirements for the ASTM F1216.

Due to the fact that fiberglass actually adds structural integrity to the composite, test results dramatically show that customers may expect strength performance from MultiLiner® far in excess of traditional composites made with felt and resin.

Relining is normally associated with reduced flow capacity and insufficient conformity to the old pipe. The unique material construction of the seamless MultiLiner® eliminates such problems.

In addition, the smooth inner surface produced using MultiLiner® actually increases the flow within the lined pipe, especially as compared to the old host pipe.

MultiLiner® is typically cured by stream. Using a small steam generator or boiler unit facilitates relining in industrial environments, confined, places, underground and even on board ships.

Air inflates the liner tightly against the inside of the pipeline and the steam is gradually added until the activation temperature is reached. After the chemical reaction has hardened the resin, postcuring begins with pure steam at 230 F/110 C. The postcuring develops full resin strength and chemical resistance. The total installation time is normally 5 to 6 hours.

With a flexural modulus in excess of 1,200,000 psi the patented MultiLiner® is the strongest CIPP liner on the market today. With such strength performance customers can expect to install liners with a much thinner wall thickness thus providing their customers with a higher flow capacity for a competitive price.

The patented MultiLiner® exceeds all the requirements for ASTM F2019. In addition MultiLiner® can also be expected to far exceed the requirements for the ASTM F1216.

Due to the fact that fiberglass actually adds structural integrity to the composite, test results dramatically show that customers may expect strength performance from MultiLiner® far in excess of traditional composites made with felt and resin.

Resistent To Abrasion And Chemicals

MultiLiner® is constructed using high quality corrosion resistant fiberglass and polyester, vinylester or epoxy resins. Furthermore the inside of the liner is covered with a resin-rich veil, forming a very smooth and glass-hard surface.

A tight fit to the existing pipe

MultiLiner® expands up to 8% in the radial axis allowing the liner to accurately follow the shape of the old pipe.

Quality and long-term behavior

The qualities of MultiLiner® are checked constantly during each production sequence and tested by independent experts